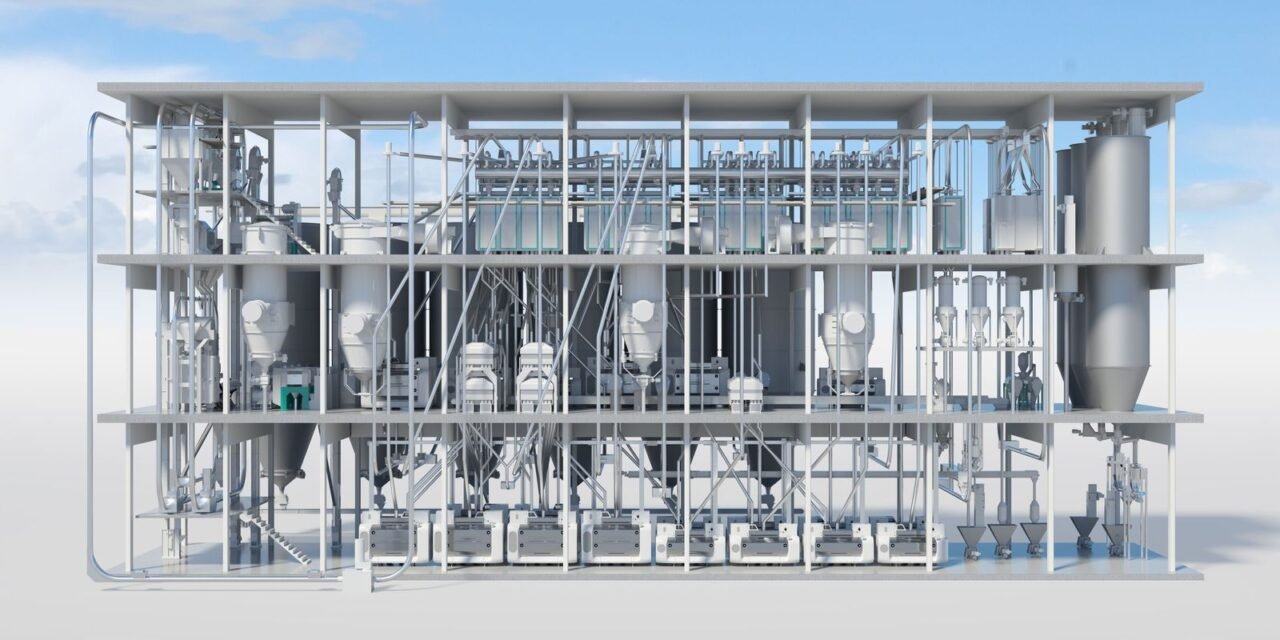

Automation is revolutionizing the grain milling industry by enhancing efficiency, improving product quality, reducing costs, and ensuring sustainability. Advanced technologies, including IoT, AI, robotics, and data analytics, are transforming traditional milling processes into highly automated, intelligent systems. Here’s how automation is driving change:

1. Enhanced Operational Efficiency

- Real-Time Monitoring: Automated systems equipped with IoT sensors provide real-time data on parameters such as temperature, moisture, particle size, and flow rates, enabling precise control over milling processes.

- Minimized Downtime: Predictive maintenance systems powered by AI analyze equipment performance to detect potential failures, reducing unplanned downtimes and repair costs.

- Continuous Operation: Automation allows mills to operate 24/7 with minimal human intervention, maximizing productivity and throughput.

2. Improved Product Quality

- Consistent Output: Automated systems maintain uniform grinding, sifting, and blending processes, ensuring consistent particle size and product quality.

- Precision Control: Advanced equipment adjusts milling settings dynamically based on grain type and desired product specifications, such as flour fineness or gluten content.

- Quality Assurance: Automated quality control systems detect impurities, contamination, or deviations in product specifications, ensuring compliance with standards.

3. Increased Productivity

- High-Speed Processing: Automation accelerates milling processes, reducing the time required for cleaning, grinding, and packaging.

- Optimized Energy Use: Systems equipped with energy-efficient drives and controls reduce energy consumption, leading to cost savings.

- Scalability: Automated mills can handle larger volumes of grain with greater flexibility, supporting industry growth.

4. Cost Reduction

- Labor Efficiency: Automation reduces the need for manual labor, minimizing costs associated with human error, training, and wages.

- Waste Minimization: Precise control over milling processes reduces grain loss and optimizes resource use.

- Process Optimization: AI-driven algorithms analyze production data to identify inefficiencies and recommend cost-saving adjustments.

5. Enhanced Safety

- Dust Control: Automated ventilation and dust collection systems mitigate explosion risks and improve workplace safety.

- Reduced Human Exposure: Robotics handle hazardous tasks like heavy lifting, cleaning, and maintenance, lowering the risk of injuries.

- Regulatory Compliance: Automated monitoring ensures adherence to safety and hygiene standards, reducing liability.

6. Data-Driven Decision Making

- Advanced Analytics: Automated systems collect and analyze vast amounts of data, providing insights into operational performance and helping optimize production strategies.

- Traceability: Digital records of production processes enhance traceability, enabling accountability and transparency across the supply chain.

- Demand Forecasting: Integrated data platforms help mills predict market demand and adjust production accordingly.

7. Sustainability and Resource Optimization

- Energy Management: Automation integrates renewable energy sources and optimizes power usage, reducing the carbon footprint of milling operations.

- Water Efficiency: Automated water systems precisely control water use in tempering processes, minimizing waste.

- Reduced Material Wastage: Sophisticated sorting and grinding technologies maximize grain utilization.

8. Integration Across Supply Chains

- Smart Grain Storage: Automated silos monitor grain conditions (e.g., temperature, humidity) and adjust storage conditions to prevent spoilage.

- Logistics Coordination: Automated systems integrate with transportation and distribution networks, ensuring seamless movement of grain and finished products.

- End-to-End Connectivity: Digital platforms link procurement, processing, and sales, providing a holistic view of the milling value chain.

9. Robotics and Advanced Machinery

- Robotic Handling: Robots handle repetitive tasks such as packaging, palletizing, and loading, increasing speed and reducing manual errors.

- Smart Sorting Systems: High-speed optical sorters use AI and imaging technologies to remove impurities with exceptional accuracy.

- Adaptive Milling Equipment: Machines automatically adjust grinding and sieving settings based on real-time input, improving efficiency.

10. Customization and Product Innovation

- Flexible Production Lines: Automation supports quick transitions between different grain types or products, enabling mills to meet diverse consumer demands.

- Specialized Products: Automated systems allow for precise customization, such as gluten-free or high-fiber flours, to cater to niche markets.

- Enhanced R&D Capabilities: Automation facilitates experimentation with new grains, blends, and formulations.

11. Challenges and Mitigation

- Initial Investment: High upfront costs of automation can be offset by long-term savings in labor, energy, and materials.

- Skill Gaps: Training programs for operators and technicians help bridge the knowledge gap in managing automated systems.

- Integration Complexity: Collaboration with technology providers ensures smooth integration of automation solutions into existing infrastructure.

Conclusion

Automation is transforming the grain milling industry by making it smarter, faster, and more sustainable. By adopting these technologies, milling operations can achieve greater efficiency, meet evolving consumer demands, and stay competitive in a rapidly changing global market.

Hashtags

#DigitalTransformation #PrecisionMilling #GrainProcessing #SmartFactory #AdvancedManufacturing #FoodSafety #EfficientProduction #GrainQuality #SmartSolutions #MillingInnovation #SustainableFood #IndustryUpdates #FoodIndustry #GrainMilling #SmartProduction #EfficientTechnology #FoodProcessing #InnovativeSolutions #GrainIndustry #SmartAutomation