The rising global demand for specialty flours is significantly impacting traditional mills, reshaping their operations, product offerings, and market strategies. Specialty flours, such as gluten-free, organic, ancient grain, and protein-enriched varieties, cater to evolving consumer preferences for health, sustainability, and dietary customization. Here’s how this trend is influencing traditional mills:

1. Diversification of Product Lines

- Impact: Traditional mills are expanding their portfolios to include specialty flours to meet growing consumer demand.

- Changes:

- Milling grains like quinoa, amaranth, buckwheat, and millet, alongside traditional wheat.

- Introducing flours made from legumes (e.g., chickpea, lentil) and nuts (e.g., almond, coconut).

- Offering organic and non-GMO certified options.

- Example: Large mills that primarily produced wheat flour are now allocating resources to produce gluten-free or ancient grain flour.

2. Investment in New Milling Technologies

- Impact: Specialty flours often require different processing techniques compared to traditional wheat flour.

- Technological Changes:

- Stone Milling: Preferred for ancient grains to preserve nutrients and flavor.

- Impact Milling: Used for producing ultra-fine flour like rice or chickpea flour.

- Dedicated Lines: Separate production lines to avoid cross-contamination (e.g., gluten-free).

- Example: Traditional mills are retrofitting their facilities with specialized equipment to handle diverse raw materials.

3. Need for Stringent Allergen Management

- Impact: Specialty flours, especially gluten-free options, require strict measures to prevent cross-contamination.

- Operational Changes:

- Segregated production lines and storage for gluten-free flours.

- Rigorous cleaning protocols and testing for allergen residues.

- Certification processes like gluten-free or kosher labeling.

- Example: Mills producing both traditional wheat and almond flour invest in separate equipment to avoid cross-contact.

4. Increased Supply Chain Complexity

- Impact: Sourcing diverse raw materials for specialty flours complicates supply chain logistics.

- Challenges:

- Ensuring a consistent supply of niche grains like teff, spelt, or einkorn.

- Verifying organic, fair-trade, or other certifications from suppliers.

- Managing price volatility for high-demand specialty grains.

- Example: Mills are establishing direct relationships with farmers to secure a steady supply of ancient grains.

5. Adaptation to Consumer Health Trends

- Impact: Rising awareness of health benefits drives demand for specialty flours.

- Key Trends:

- Protein-enriched flours (e.g., pea or lentil) appeal to fitness-focused consumers.

- High-fiber flours (e.g., whole grain, coconut) support gut health trends.

- Low-carb and keto-friendly options like almond or flaxseed flour.

- Example: Traditional mills are reformulating products to align with these health-focused trends.

6. Increased Competition and Market Pressure

- Impact: Specialty flour producers, including small artisanal mills and global brands, are challenging traditional mills.

- Response:

- Launching premium product lines to compete in the specialty segment.

- Collaborating with food brands and retailers to develop exclusive products.

- Targeting niche markets, such as paleo or gluten-free consumers.

- Example: Traditional mills are partnering with bakeries to co-brand specialty flours for retail shelves.

7. Emphasis on Sustainability

- Impact: Specialty flours align with sustainability-focused consumer preferences.

- Operational Adjustments:

- Producing flours from upcycled ingredients, like spent grains from brewing.

- Use grains that require less water and fertilizer, such as millet or sorghum.

- Transitioning to eco-friendly packaging for specialty products.

- Example: Mills producing organic and ancient grain flours highlight their lower environmental footprint in marketing campaigns.

8. Higher Margins but Increased Costs

- Impact: Specialty flours command premium prices but often incur higher production costs.

- Financial Implications:

- Investment in certifications (e.g., organic, gluten-free) increases costs.

- Smaller production runs for niche flours reduce economies of scale.

- Research and development (R&D) for new product formulations.

- Example: While almond flour offers higher profit margins, its production cost is significantly higher than wheat flour.

9. Expansion into E-Commerce and Direct-to-Consumer (DTC)

- Impact: The rise of online shopping has expanded market opportunities for specialty flours.

- Changes:

- Launching DTC platforms to cater to health-conscious consumers.

- Leveraging subscription models for recurring sales of gluten-free or organic flour.

- Developing smaller, home-friendly packaging sizes for e-commerce.

- Example: Traditional mills are selling specialty flours on platforms like Amazon and their own websites to reach a broader audience.

10. Regulatory and Compliance Challenges

- Impact: Specialty flours often require additional certifications and compliance measures.

- Adjustments:

- Meeting specific standards for organic, non-GMO, and allergen-free labels.

- Navigating export regulations for niche grains in international markets.

- Testing for contaminants, like mycotoxins, common in non-wheat grains.

- Example: Exporting quinoa flour requires compliance with different pesticide residue standards across countries.

11. Focus on Innovation and Product Differentiation

- Impact: Developing unique products helps mills stand out in a competitive market.

- Examples of Innovations:

- Blended flours combining traditional and specialty grains (e.g., wheat-quinoa mix).

- Functional flours with added nutrients like prebiotics or probiotics.

- Instant and ready-to-use specialty flour mixes for convenience-focused consumers.

- Example: A traditional mill launches a protein-rich pancake mix using chickpea and almond flour.

12. Consumer Education and Marketing

- Impact: Raising awareness about the benefits of specialty flours drives adoption.

- Strategies:

- Highlighting health benefits and culinary versatility in marketing materials.

- Partnering with chefs and influencers to showcase specialty flour recipes.

- Providing clear labeling for dietary preferences (e.g., “gluten-free,” “keto-friendly”).

- Example: A mill markets teff flour as a high-protein, gluten-free option for Ethiopian-inspired recipes.

13. Collaboration with Food Manufacturers

- Impact: Specialty flours are increasingly used as ingredients in packaged goods.

- Applications:

- Gluten-free bread, cookies, and pasta.

- High-protein snacks like bars and chips.

- Paleo and keto-friendly baked goods.

- Example: Traditional mills supply chickpea flour to snack brands creating grain-free chips.

Conclusion

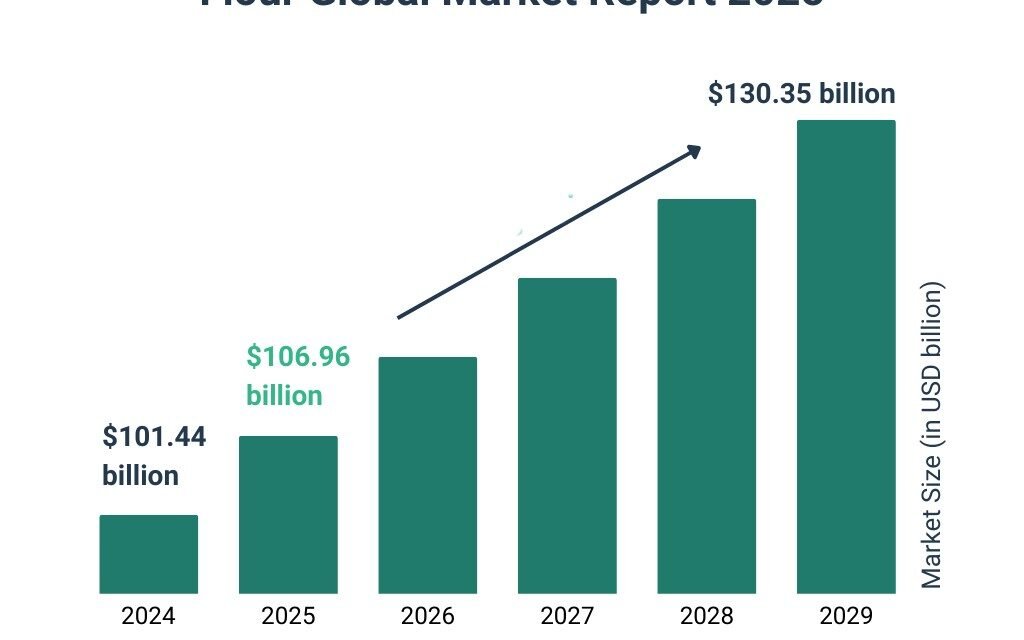

The global demand for specialty flours is transforming traditional mills by pushing them to diversify products, adopt new technologies, and meet evolving consumer preferences. While this shift presents challenges, such as increased costs and supply chain complexities, it also offers significant opportunities for growth and profitability in a rapidly expanding market. Traditional mills that adapt to these trends through innovation, sustainability, and collaboration are well-positioned to thrive in the evolving industry landscape.

Hashtags

#SustainableFarming #OrganicFlour #GlutenFreeOptions #AncientGrains #FlourAlternatives #BakingEssentials #NutritionBenefits #FarmToTable #FlourPower #FoodieFinds #FlourishYourRecipes #FlourGoals #BreadMaking #FlourishYourHealth #FlourishYourLife #FlourishYourTasteBuds #FlourishYourWellness #FlourishYourKitchen #FlourishYourPlate #FlourishYourPassion