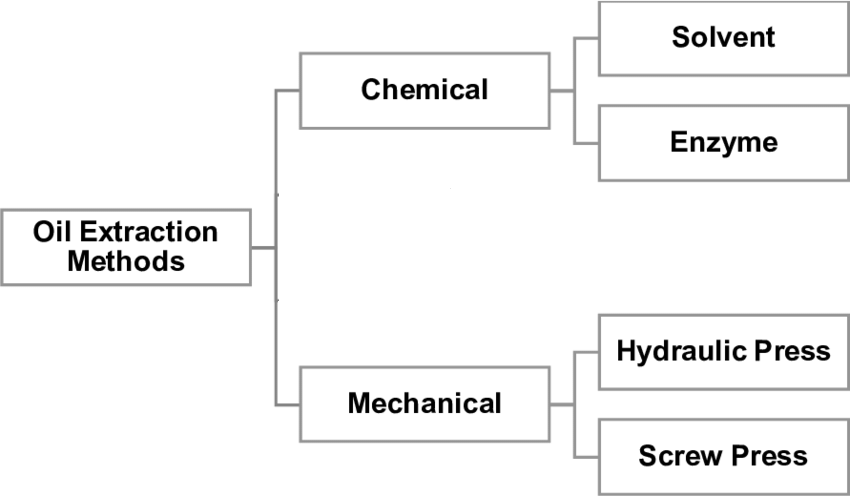

Mechanical and chemical oil extraction processes are two primary methods used to extract oils from seeds, nuts, and other raw materials. Each has distinct mechanisms, advantages, and applications, catering to different needs in industries such as food, cosmetics, and biofuels. Here’s a detailed comparison of the two processes:

1. Extraction Process

Mechanical Extraction

- Mechanism: Uses physical force to press oil from raw materials.

- Steps:

- Seeds or nuts are cleaned, dried, and sometimes preconditioned (e.g., heated or flaked).

- The material is pressed using equipment like hydraulic or screw presses.

- Example: Cold-pressed oils like extra virgin olive oil or unrefined sesame oil.

Chemical Extraction

- Mechanism: Uses solvents (most commonly hexane) to dissolve and extract oils.

- Steps:

- The material is crushed and mixed with a solvent, which dissolves the oil.

- The solvent-oil mixture is separated, and the solvent is evaporated or distilled, leaving the oil behind.

- Example: Refined soybean or corn oil.

2. Efficiency

Mechanical Extraction

- Efficiency: Typically extracts 60–80% of the oil content, leaving some residual oil in the press cake.

- Limitation: Less effective for seeds with low oil content or hard structures, such as soybeans or rice bran.

Chemical Extraction

- Efficiency: Extracts up to 95–99% of the oil, achieving near-complete recovery.

- Advantage: Suitable for large-scale operations and low-oil-content seeds.

3. Quality of Oil

Mechanical Extraction

- Quality: Produces higher-quality, unrefined oils with minimal processing.

- Retains natural flavors, colors, and nutrients (e.g., antioxidants, vitamins).

- Often used for premium or specialty oils.

- Limitation: Oils may have a shorter shelf life due to higher moisture and impurities.

Chemical Extraction

- Quality: Produces oils that are neutral in flavor, color, and aroma after refining.

- Ideal for processed foods and applications where a bland oil is desired.

- May lose some nutrients during refining steps.

- Limitation: Further refining is required to remove solvent residues and impurities.

4. Environmental Impact

Mechanical Extraction

- Impact: Environmentally friendly with no chemical solvents involved.

- Produces by-products like press cake that can be used as animal feed or fertilizer.

- Limitation: Generates lower yields, which may lead to higher raw material use.

Chemical Extraction

- Impact: Involves the use of chemical solvents, which can pose environmental and safety risks.

- Solvent recovery systems minimize waste but require energy-intensive processes.

- Limitation: Potential for solvent residues in the oil or meal if not properly refined.

5. Cost

Mechanical Extraction

- Initial Cost: Lower initial investment in equipment compared to chemical methods.

- Operational Cost: Lower energy requirements but less oil yield can increase material costs.

- Scale: Best suited for small- to medium-scale production.

Chemical Extraction

- Initial Cost: Higher investment in equipment for solvent recovery and refining.

- Operational Cost: Higher due to energy-intensive steps like distillation.

- Scale: Economically viable for large-scale production with high throughput.

6. Applications

Mechanical Extraction

- Uses:

- Producing cold-pressed or virgin oils for direct consumption (e.g., olive oil, coconut oil).

- Small-scale and artisanal oil production.

- Examples: Specialty oils used in gourmet foods or cosmetics.

Chemical Extraction

- Uses:

- Large-scale production of refined oils for processed foods, frying, or industrial use.

- Extraction of oils from low-oil-content materials like soybeans or rice bran.

- Examples: Soybean oil for margarine, and biodiesel production.

7. Residual Material Handling

Mechanical Extraction

- By-Products: Produces press cake with higher residual oil content, often used as livestock feed.

- Value: Nutrient-rich by-products can add value to agricultural supply chains.

Chemical Extraction

- By-Products: Produces defatted meal with minimal oil content.

- Value: High-protein meal suitable for animal feed or further processing into protein isolates.

8. Safety Considerations

Mechanical Extraction

- Safety: Safer to operate as it doesn’t involve flammable or toxic chemicals.

- Limitation: Potential risks include overheating during pressing, which can degrade oil quality.

Chemical Extraction

- Safety: Requires strict controls to manage flammable solvents and prevent exposure.

- Proper ventilation and solvent recovery systems are essential.

- Limitation: Accidents like solvent leaks or fires can pose significant risks.

9. Consumer Preferences

Mechanical Extraction

- Consumer Appeal: Preferred for natural, organic, or minimally processed products.

- Trends: Increasing demand for cold-pressed oils in health and wellness markets.

Chemical Extraction

- Consumer Appeal: Widely accepted for refined oils used in everyday cooking and industrial applications.

- Trends: Growing scrutiny of chemical processes and shift toward more sustainable methods.

Conclusion

Both mechanical and chemical oil extraction processes have distinct advantages and are suited to different applications. Mechanical extraction is ideal for high-quality, minimally processed oils, aligning with consumer preferences for natural products. In contrast, chemical extraction excels in large-scale operations where maximum yield and cost-efficiency are prioritized. The choice between these methods depends on the type of raw material, desired product characteristics, scale of production, and market demands.

Hashtags

#OilExtraction #MechanicalExtraction #ChemicalProcessing #FoodInnovation #SustainableTech #ChemicalVsMechanical #OilTrends #InnovativeTech #NaturalProcessing #FoodSolutions #EcoFriendlyTech #OilProduction #EfficientProcessing #FoodIndustry #SustainableSolutions #ChemicalIndustry #MechanicalIndustry #OilTech #ProcessingMethods #EcoFriendlyExtraction