Innovations in cold-press oil extraction techniques have focused on improving efficiency, oil quality, sustainability, and scalability. These advancements cater to the growing demand for natural, chemical-free, and nutrient-rich oils in food, cosmetics, and health industries. Here are some key innovations:

1. Advanced Pressing Mechanisms

- Innovation: Enhanced screw and hydraulic presses for higher yield and efficiency.

- Features:

- Variable Compression Settings: Allow precise control over pressure to optimize oil extraction for different seeds and nuts.

- Dual-Stage Pressing: Increases oil yield without heating, maintaining “cold-press” standards.

- Low-Friction Screws: Reduce heat generation during pressing, preserving nutrients.

- Impact: Extracts more oil with less energy while retaining the natural flavor and nutrients.

- Example: Dual-stage cold-press machines for high-fat seeds like sunflower and sesame.

2. Pre-Treatment of Raw Materials

- Innovation: Pre-conditioning seeds and nuts to improve oil extraction.

- Techniques:

- Cryogenic Treatment: Freezing raw materials to break cell walls and enhance oil release.

- Ultrasound-Assisted Pre-Treatment: Ultrasound-Assisted Pre-Treatment uses ultrasonic waves to disrupt seed structure, increasing oil yield.

- Microwave Conditioning: Softens seeds to improve pressing efficiency without overheating.

- Impact: Boosts yield, reduces energy use, and ensures better quality oils.

- Example: Microwave-preconditioned flaxseeds yield more oil with higher omega-3 content.

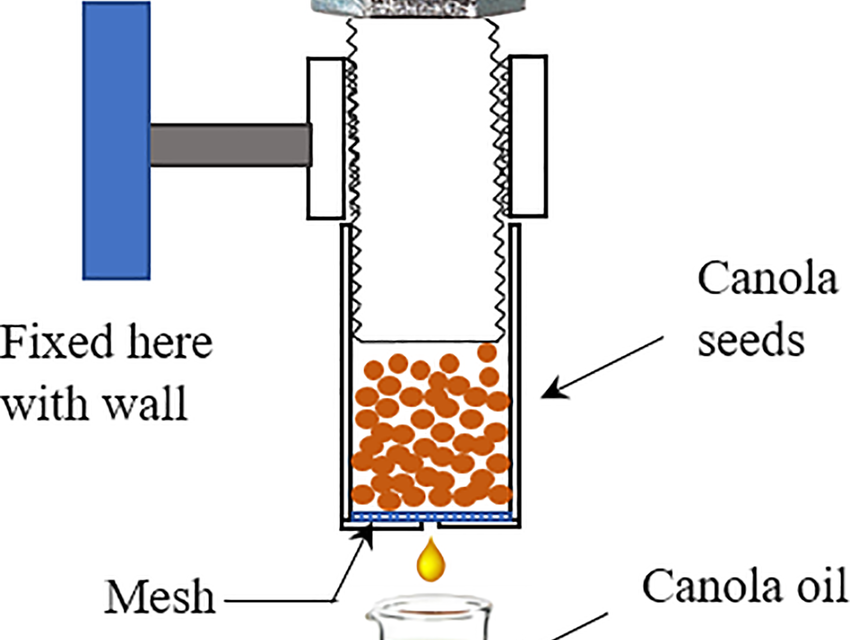

3. Enhanced Filtration Systems

- Innovation: Advanced filtration to improve oil clarity and quality post-extraction.

- Features:

- Cold-Centrifugation: Separates solids and impurities at low temperatures without compromising oil quality.

- Membrane Filtration: Removes micro-impurities while preserving nutrients and antioxidants.

- Activated Carbon Filters: Reduce natural pigments for lighter-colored oils.

- Impact: Produces cleaner, premium-grade oils suitable for high-value markets like cosmetics and health supplements.

- Example: Cold-centrifugation is widely used in olive oil production for extra virgin quality.

4. Integration of Automation and IoT

- Innovation: Smart cold-press systems with real-time monitoring and automation.

- Features:

- IoT Sensors: Monitor temperature, pressure, and throughput to maintain optimal conditions.

- Automated Adjustments: Ensure consistent oil quality by dynamically adjusting settings during pressing.

- Data Analytics: Track operational performance for predictive maintenance and efficiency improvements.

- Impact: Reduces operational errors, enhances productivity, and ensures consistent oil quality.

- Example: IoT-enabled cold-press machines used in large-scale organic oil production.

5. Sustainable and Energy-Efficient Designs

- Innovation: Machines designed for low energy consumption and minimal waste.

- Features:

- Energy Recovery Systems: Reuse heat generated in other processes to reduce energy waste.

- Eco-Friendly Materials: Use of stainless steel and recyclable components for machinery.

- Zero-Waste Systems: Convert press cakes (residual material) into animal feed, biofuel, or food products.

- Impact: Reduces carbon footprint and improves the overall sustainability of oil production.

- Example: Press cakes from coconut oil extraction are repurposed as gluten-free flour.

6. Improved Temperature Control

- Innovation: Precision temperature management to maintain the “cold-press” standard (typically below 45°C or 113°F).

- Features:

- Cooling Jackets: Surround pressing components to dissipate heat and maintain low temperatures.

- Liquid Nitrogen Cooling: Advanced cooling systems for delicate seeds prone to heat damage.

- Thermal Sensors: Ensure temperatures remain within the ideal range for nutrient preservation.

- Impact: Preserves sensitive compounds like polyunsaturated fats, vitamins, and antioxidants.

- Example: Cooling systems in avocado oil extraction retain its rich vitamin E and omega-9 content.

7. Customizable Multi-Seed Machines

- Innovation: Machines designed to handle a variety of seeds, nuts, and fruits with customizable settings.

- Features:

- Interchangeable Press Heads: Allow quick changeovers for different raw materials.

- Programmable Parameters: Store presets for optimal extraction conditions for each seed type.

- Compact Designs: Suitable for small-scale producers catering to niche markets.

- Impact: Increases versatility and efficiency, especially for artisanal or small-scale producers.

- Example: Multi-seed cold-press machines used for flaxseed, chia, and pumpkin seeds.

8. High-Yield Small-Scale Systems

- Innovation: Mini cold-press machines designed for small-scale or at-home production.

- Features:

- Compact and Portable Units: Suitable for farmers, micro-businesses, or personal use.

- User-Friendly Interfaces: Simplify operation for non-industrial users.

- Low-Power Consumption: Designed to run on minimal energy.

- Impact: Democratizes cold-press oil production and promotes farm-to-table concepts.

- Example: Tabletop cold-press machines for home production of oils like peanut or sesame.

9. Hybrid Cold-Press Systems

- Innovation: Combining cold-pressing with other non-thermal techniques for enhanced results.

- Techniques:

- Enzymatic Treatment: Uses enzymes to break down seed cell walls for better oil extraction.

- Supercritical CO₂ Extraction: Enhances cold-pressing by using CO₂ to dissolve and extract oils gently.

- Vacuum-Assisted Pressing: Reduces oxygen exposure to prevent oxidation during extraction.

- Impact: Produces oils with higher purity and nutritional value.

- Example: Hybrid systems for specialty oils like hempseed or moringa.

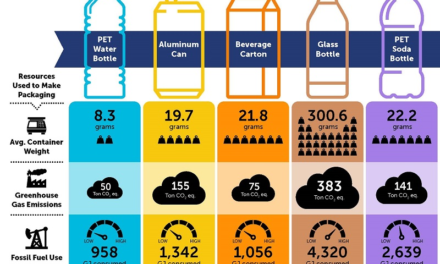

10. Innovations in Packaging Integration

- Innovation: On-site packaging systems integrated with cold-press machines.

- Features:

- Nitrogen Flushing: Removes oxygen from bottles to prevent oxidation and extend shelf life.

- Eco-Friendly Packaging: Directly fill biodegradable or recyclable containers post-extraction.

- Automated Bottling Lines: Streamline production for large-scale operations.

- Impact: Reduces handling time, minimizes contamination, and enhances product freshness.

- Example: Cold-pressed oil producers using nitrogen-flushed glass bottles for premium products.

11. Focus on Specialty Oils

- Innovation: Equipment tailored for extracting niche oils with high-value markets.

- Examples:

- CBD Oil Extraction: Specialized presses for hemp seeds that retain cannabinoids.

- Essential Oil Production: Dual-purpose machines that extract both fixed and volatile oils.

- Exotic Oils: Equipment designed for rare seeds like argan, black cumin, or baobab.

- Impact: Expands market opportunities for high-margin, low-volume products.

- Example: Cold-press systems for argan oil production in Morocco.

12. Enhanced Quality Assurance

- Innovation: Real-time monitoring and analysis of oil quality during extraction.

- Features:

- Spectrometers and Sensors: Analyze purity, color, and nutrient content on-site.

- Automated Feedback Loops: Adjust pressing conditions based on quality measurements.

- Blockchain Integration: Tracks raw material origin and extraction conditions for transparency.

- Impact: Ensures consistent quality, which is critical for premium and health-focused markets.

- Example: Sensors that measure the polyphenol content in olive oil during extraction.

Conclusion

Innovations in cold-press oil extraction are making the process more efficient, sustainable, and versatile while maintaining the high quality and nutritional benefits that define these oils. By integrating advanced technologies like IoT, hybrid systems, and precision temperature control, producers can meet the growing consumer demand for natural, unrefined, and health-promoting oils. These advancements not only improve production efficiency but also open new opportunities in niche and specialty markets.

Hashtags

#OrganicOil #CleanEating #ColdPressedGoodness #NutrientRich #EcoConscious #FarmToTable #HealthyHabits #GreenLiving #NaturalBeauty #WellnessJourney #PlantBased #NourishYourBody #SustainableFarming #HealthyChoices #HolisticHealth #CleanEats #FarmFresh #WholeFoods #HealthyLifestyle #NutritionMatters