The oil extraction process plays a critical role in determining the flavor profile of edible oils. Different methods of extraction influence the presence of natural compounds, such as fatty acids, antioxidants, and volatile flavor compounds, resulting in oils with varying taste, aroma, and sensory characteristics. Below are the key ways oil extraction processes impact flavor:

1. Cold Pressing

- Process: Involves mechanically pressing oilseeds or nuts at low temperatures (below 50°C/122°F) without the use of chemicals or heat.

- Flavor Impact:

- Retains natural flavors, aromas, and nutrients, resulting in oils with a robust and distinctive taste.

- For example, cold-pressed olive oil has a fruity, grassy, or peppery flavor, while sesame oil retains its nutty profile.

- Minimal processing can leave some impurities, contributing to a raw or earthy taste.

2. Expeller Pressing

- Process: Mechanical pressing with some heat generated due to friction.

- Flavor Impact:

- Produces a more neutral flavor compared to cold pressing but retains mild nutty or seed-specific notes.

- May introduce slight roasted or toasted notes, especially in oils like sesame, due to the higher temperatures.

- Less aromatic than cold-pressed oils but retains more flavor than refined oils.

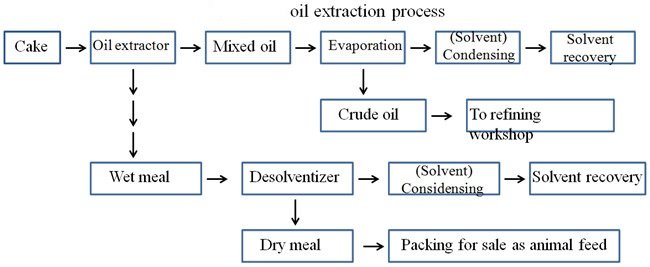

3. Solvent Extraction

- Process: Chemical solvents (e.g., hexane) are used to extract oil from seeds or nuts, followed by refining.

- Flavor Impact:

- Produces highly neutral-tasting oils due to the extensive refining process that removes impurities and flavor compounds.

- Ideal for applications where a neutral flavor is required (e.g., soybean oil, canola oil).

- Strips away natural aromas, which may be undesirable for gourmet or specialty oils.

4. Refining

- Process: Includes degumming, neutralization, bleaching, and deodorization to remove impurities, free fatty acids, and odors.

- Flavor Impact:

- Removes most natural flavors, leaving the oil almost tasteless and odorless (e.g., refined sunflower oil or palm oil).

- While this is beneficial for culinary applications where the oil should not overpower the dish, it lacks the characteristic flavor of unrefined or minimally processed oils.

5. Centrifugal Extraction

- Process: Centrifugation is used to separate oil from water and solids, and it is often used in high-quality olive oil production.

- Flavor Impact:

- Retains delicate, aromatic, and complex flavors, as no heat or chemicals are used.

- Preserves volatile compounds that contribute to the unique taste of premium oils.

6. Enzymatic Extraction

- Process: Uses enzymes to break down cell walls in oilseeds, releasing oil without high heat or chemicals.

- Flavor Impact:

- Maintains the natural flavor of the oil while reducing bitterness or harsh notes often present in raw oils.

- The process enhances subtle flavor nuances, making it ideal for high-quality or gourmet oils.

7. Roasting Before Extraction

- Process: Seeds or nuts are roasted before mechanical pressing or expeller pressing.

- Flavor Impact:

- Imparts rich, roasted, or nutty flavors to the oil, as seen in roasted sesame oil or peanut oil.

- Enhances the aromatic profile, making the oil suitable for culinary applications that benefit from bold, intense flavors.

8. Fractionation

- Process: Separates oil into fractions based on melting points to produce oils with specific properties.

- Flavor Impact:

- Typically used for technical purposes rather than flavor enhancement.

- The process can slightly modify the taste by isolating specific fat compositions but usually results in a neutral flavor.

9. Fermentation-Based Extraction

- Process: Uses microbial fermentation to extract oil from seeds or algae.

- Flavor Impact:

- It can result in oils with complex, umami-like notes or other distinct flavors, depending on the fermentation process.

- It is not yet widely adopted in the food industry but shows potential for creating unique flavor profiles.

10. Impact of Heat and Oxidation

- Overheating During Extraction:

- Excessive heat can degrade volatile flavor compounds and antioxidants, leading to bland or burnt-tasting oils.

- It can also produce undesirable off-flavors due to lipid oxidation.

- Oxidation and Rancidity:

- Improper handling during or after extraction can lead to oxidation, giving the oil a stale or rancid flavor.

Key Takeaways for Different Oil Types:

- Extra Virgin Olive Oil: Cold-pressed or centrifugally extracted, retaining fruity, grassy, or peppery flavors.

- Refined Oils (e.g., Soybean, Canola): Solvent-extracted and refined, resulting in neutral flavors suitable for versatile cooking.

- Specialty Oils (e.g., Sesame, Walnut): Often roasted and mechanically pressed, enhancing nutty or toasted profiles.

- Coconut Oil: Cold-pressed for a raw, coconut-like flavor; refined versions are neutral-tasting.

Conclusion

The extraction method significantly impacts the flavor profile of oils. While cold pressing and minimal processing retain natural flavors and nutrients, refining and solvent extraction result in neutral-tasting oils suited for culinary versatility. Manufacturers choose the extraction method based on the intended use and desired flavor characteristics of the oil.

Hashtags

#SustainableFarming #OrganicOil #HealthyEating #FarmToTable #NutrientRich #GourmetCooking #ArtisanalOils #FarmFresh #EcoFriendly #SmallBatch #PremiumQuality #HealthBenefits #FarmersMarket #LocallySourced #Handcrafted #NaturallyDelicious #CleanEating #FarmersPride #FarmToFork #FarmersMarketFinds