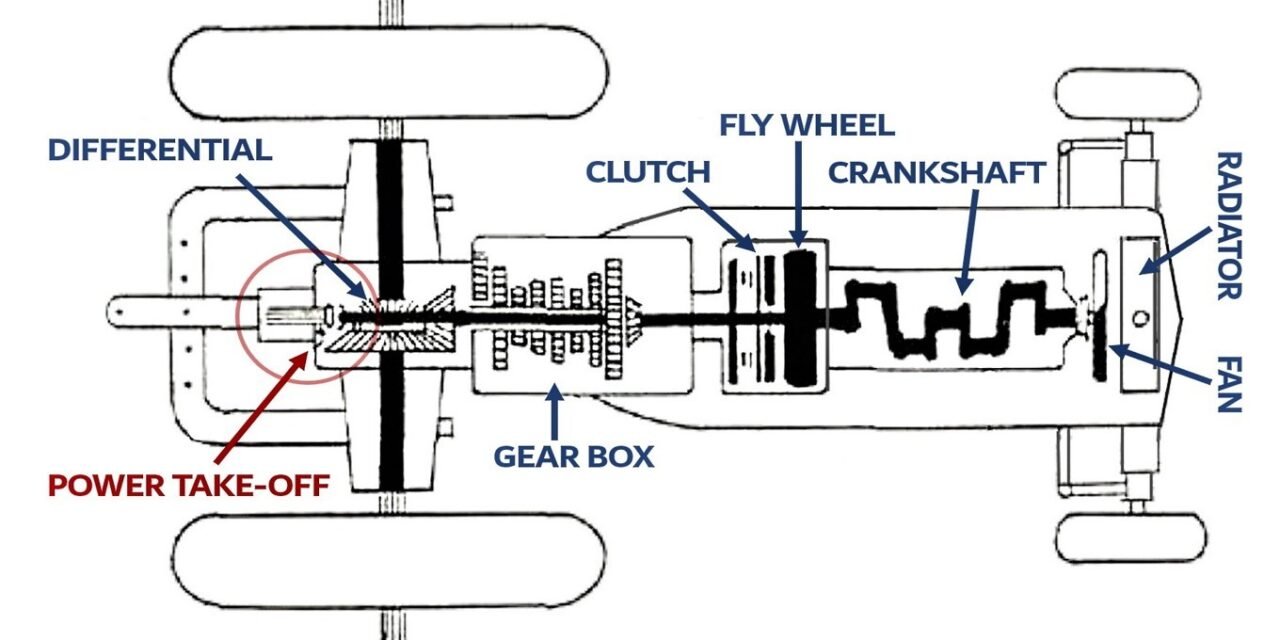

The Power Take-Off (PTO) on a tractor is a crucial feature that transfers power from the tractor’s engine to external implements and attachments, such as mowers, tillers, balers, sprayers, and post-hole diggers. Here’s an explanation of how it works and its key components:

How a Tractor PTO Works

- Connection to the Tractor Engine:

- The PTO shaft is mechanically linked to the tractor’s engine or transmission.

- When engaged, it rotates to transmit engine power to the attached implement.

- Attachment of Implements:

- The implement to be powered has a drive shaft that connects to the tractor’s PTO shaft using a universal joint.

- This connection allows the implement to draw power from the tractor’s engine.

- Control System:

- A lever, button, or switch on the tractor allows the operator to engage or disengage the PTO as needed.

- Depending on the tractor, the PTO may be engaged either manually or electronically.

- Power Transmission:

- Once engaged, the PTO shaft rotates at a set speed (measured in revolutions per minute or RPM) to drive the implement.

- Common PTO speeds are 540 RPM (standard for most implements) and 1000 RPM (used for high-power applications).

- Safety Features:

- Modern PTO systems often include shields, covers, and guards to prevent accidental contact with the rotating shaft.

- Some systems have an overrunning clutch or slip clutch to protect both the tractor and the implement from damage in case of sudden stops.

Types of Tractor PTO Systems

- Transmission PTO:

- Directly connected to the tractor’s transmission.

- The PTO stops when the tractor clutch is disengaged, making it less convenient for certain tasks.

- Common in older tractors.

- Independent PTO:

- Operates independently of the tractor’s transmission and clutch.

- Allows the PTO to keep running even when the tractor is stopped or its clutch is disengaged.

- Found in most modern tractors.

- Live PTO:

- Uses a two-stage clutch system:

- Half-press: Disengages the tractor’s transmission but keeps the PTO running.

- Full-press: Disengages both the transmission and PTO.

- Allows smoother operation of PTO-powered implements.

- Uses a two-stage clutch system:

- Ground Speed PTO:

- The PTO speed is synchronized with the tractor’s ground speed, making it useful for specific applications like seeders or fertilizer spreaders.

Uses of a PTO

- Mowing: Powers rotary cutters and finishing mowers.

- Tilling: Drives rotary tillers for soil preparation.

- Planting and Harvesting: Operates seeders, planters, and balers.

- Spraying: Runs pumps for pesticide or fertilizer sprayers.

- Post-Hole Digging: Provides power for augers.

- Snow Removal: Drives snow blowers and rotary brooms.

Benefits of PTO Systems

- Versatility: Enables tractors to power a wide range of implements for various tasks.

- Efficiency: Uses the tractor’s engine power efficiently to reduce manual labor.

- Productivity: Allows faster and more reliable operation of implements compared to manual methods.

Safety Tips for Using a PTO

- Use Shields and Guards: Always ensure the PTO shield and driveline guards are in place to prevent accidents.

- Turn Off the PTO When Not in Use: Disengage the PTO before dismounting the tractor or inspecting the implement.

- Keep Clothing and Body Parts Away: Avoid loose clothing and stay clear of the rotating PTO shaft.

- Follow Manufacturer Instructions: Use only compatible implements and follow the manufacturer’s guidelines for proper operation.

Conclusion

The tractor PTO is an essential feature that significantly enhances the tractor’s functionality by enabling it to power external implements. Its design ensures efficient energy transfer and ease of use, making it indispensable for modern farming and industrial applications.

Hashtags

#AgriInnovation #FarmingTechnology #PTOAdvancements #EfficientFarming #SmartAg #SustainableAg #PrecisionFarming #FarmMechanization #TractorPower #AgriEquipment #FarmingSolutions #PTOUses #ModernFarming #TractorTools #AgriMachinery #PTOEngineering #InnovativeFarming #FarmMechanics #TractorUpgrades #AgriTechRevolution