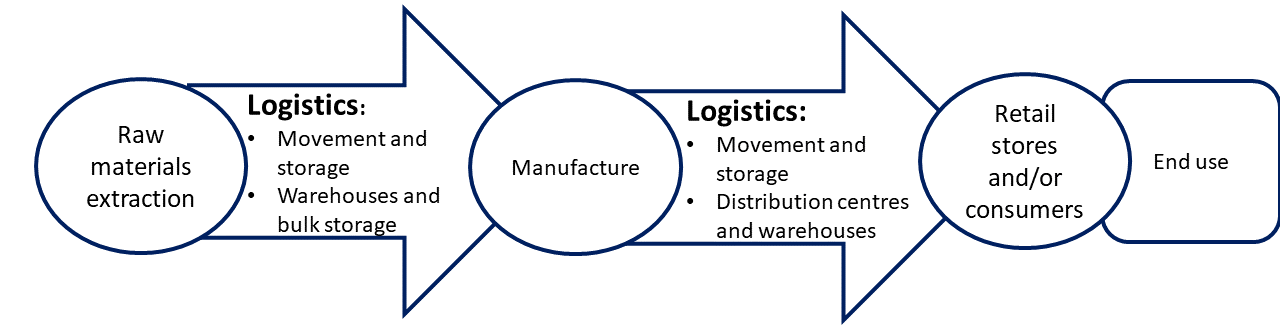

Managing supply chain logistics for perishable goods is complex and requires meticulous planning to maintain quality and minimize spoilage. Here are key strategies companies use to handle this effectively:

1. Cold Chain Management

- Temperature-Controlled Storage and Transportation:

- Use refrigerated trucks, containers, and warehouses to maintain optimal temperatures.

- Monitor and control temperature and humidity levels at all stages of the supply chain.

- Real-Time Monitoring:

- IoT-enabled sensors track conditions like temperature, humidity, and shock during transit.

- Alerts notify stakeholders of deviations to take corrective actions immediately.

2. Efficient Transportation

- Direct Routes:

- Minimize transit time by using direct or express shipping methods where possible.

- Multi-Modal Logistics:

- Combine air, sea, and land transport to optimize speed and cost while maintaining quality.

- Pre-Approved Customs Clearance:

- Use expedited customs processes to reduce delays at borders or ports.

3. Inventory and Demand Forecasting

- Just-In-Time (JIT) Inventory:

- Produce and ship goods based on accurate demand forecasts to avoid overstocking or spoilage.

- Predictive Analytics:

- Leverage AI and machine learning to anticipate demand fluctuations and align production and distribution schedules.

4. Packaging Solutions

- Specialized Packaging:

- Use insulated, vacuum-sealed, or nitrogen-flushed packaging to preserve freshness and extend shelf life.

- Smart Packaging:

- Incorporate technology like freshness indicators or RFID tags to monitor product conditions.

5. Collaboration with Reliable Partners

- Third-Party Logistics (3PL):

- Partner with 3PL providers experienced in handling perishable goods and equipped with advanced cold chain facilities.

- Supplier Relationships:

- Work closely with suppliers to ensure the timely production and dispatch of high-quality goods.

6. Dynamic Route Optimization

- Use GPS and AI-based software to plan optimal delivery routes in real time, accounting for traffic, weather, and road conditions.

7. Regulatory Compliance

- Food Safety Standards:

- Ensure compliance with local and international food safety regulations (e.g., HACCP, FSMA, or EU standards).

- Documentation and Traceability:

- Maintain detailed records to trace products throughout the supply chain.

8. Risk Mitigation Plans

- Backup Systems:

- Have contingency plans for equipment failures, such as backup refrigeration units or alternative transport modes.

- Insurance:

- Protect against losses from spoilage, delays, or accidents.

9. Training and Awareness

- Train employees and partners in handling perishable goods to ensure adherence to protocols and reduce the risk of human error.

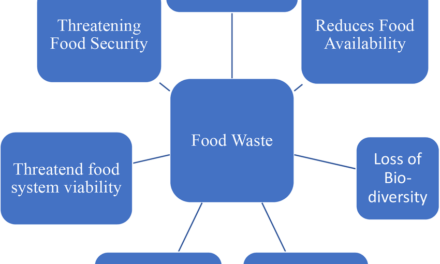

10. Sustainability Practices

- Waste Reduction:

- Repurpose or donate near-expiry goods to minimize waste.

- Energy-Efficient Technologies:

- Use renewable energy and eco-friendly cooling systems to reduce environmental impact.