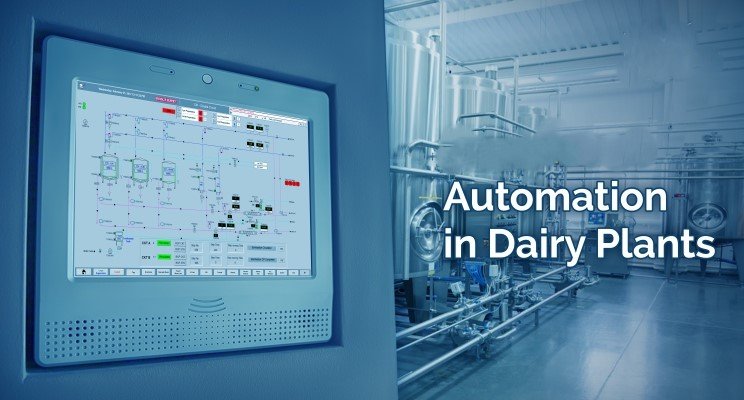

Automation is revolutionizing dairy processing plants by enhancing efficiency, reducing costs, and ensuring consistent product quality. It allows for precise control over production processes, minimizes human error, and facilitates scalability to meet growing demand. Here’s how automation is improving efficiency in dairy processing plants:

1. Streamlined Milk Reception and Quality Control

- Automation in Action:

- Automated milk reception systems measure volume, temperature, and fat content upon arrival.

- Inline sensors detect contaminants or deviations from quality standards in real-time.

- Efficiency Gains:

- Faster processing of incoming milk reduces delays and spoilage risk.

- Eliminates manual testing errors and ensures consistent quality.

- Example: Inline analyzers that measure fat, protein, and microbial counts directly in the pipeline.

2. Precise Standardization and Homogenization

- Automation in Action:

- Automated systems control the blending of milk to standardize fat content and consistency.

- Homogenizers use automated pressure adjustments to break down fat globules uniformly.

- Efficiency Gains:

- Consistent product quality with minimal manual intervention.

- Reduced wastage of raw materials during standardization.

- Example: Automated valves adjust ingredient ratios based on preset product specifications.

3. Efficient Pasteurization

- Automation in Action:

- Automated heat exchangers regulate temperatures for pasteurization, ensuring precise heat treatment.

- Continuous monitoring of pasteurization parameters like temperature, flow rate, and time.

- Efficiency Gains:

- Ensures compliance with safety standards while optimizing energy use.

- Reduces the risk of under- or over-pasteurization, improving yield.

- Example: High-efficiency pasteurization systems with automated CIP (clean-in-place) functionality.

4. Advanced Cleaning and Sanitation (CIP Systems)

- Automation in Action:

- Clean-in-place systems automate cleaning cycles for tanks, pipelines, and equipment.

- Sensors monitor cleaning agent concentrations, temperature, and flow.

- Efficiency Gains:

- Reduces downtime between production runs.

- Minimizes water and chemical use while ensuring thorough sanitation.

- Example: Automated CIP systems that clean and sanitize in less time compared to manual methods.

5. Real-Time Monitoring and Data Analytics

- Automation in Action:

- IoT-enabled sensors collect real-time data on temperature, pressure, and product flow.

- Data analytics platforms provide actionable insights into plant performance and maintenance needs.

- Efficiency Gains:

- Proactive issue detection reduces downtime and maintenance costs.

- Optimizes production scheduling based on real-time data.

- Example: SCADA (Supervisory Control and Data Acquisition) systems for centralized plant monitoring.

6. Robotic Filling and Packaging

- Automation in Action:

- Robotic systems handle tasks like bottle filling, capping, labeling, and sealing.

- Vision systems ensure proper alignment and defect-free packaging.

- Efficiency Gains:

- Increases packaging speed and reduces labor costs.

- Ensures precision, reducing spillage and packaging waste.

- Example: High-speed filling machines for milk cartons with automated leak detection.

7. Energy Efficiency in Processing

- Automation in Action:

- Automated energy management systems monitor and optimize energy usage across the plant.

- Heat recovery systems reuse energy from pasteurization for other processes.

- Efficiency Gains:

- Reduces energy costs and carbon footprint.

- Enhances sustainability without compromising production efficiency.

- Example: Heat exchangers that capture and reuse heat from cooling or pasteurization.

8. Inventory Management

- Automation in Action:

- Automated systems track raw materials, ingredients, and finished goods in real time.

- Integration with ERP (Enterprise Resource Planning) systems ensures inventory optimization.

- Efficiency Gains:

- Reduces waste due to overstocking or expired inventory.

- Improves order fulfillment accuracy and speed.

- Example: RFID-tagged crates of dairy products tracked through automated warehouse systems.

9. Waste Management

- Automation in Action:

- Automated separators and filters manage by-products like whey or wastewater.

- Systems optimize the use of by-products for secondary products or energy generation.

- Efficiency Gains:

- Reduces waste disposal costs and creates additional revenue streams.

- Enhances environmental compliance.

- Example: Automated systems that convert dairy wastewater into biogas for plant operations.

10. Flexible Production Lines

- Automation in Action:

- Modular automation systems allow plants to switch between product types (e.g., milk, yogurt, cheese) with minimal downtime.

- Recipe management systems adjust production parameters for different product specifications.

- Efficiency Gains:

- Enables rapid adaptation to market demands and seasonal variations.

- Reduces setup time for new product lines.

- Example: Automated systems capable of producing both flavored and plain yogurt on the same line.

11. Workforce Optimization

- Automation in Action:

- Robots and automated systems take over repetitive or hazardous tasks.

- Operators focus on monitoring and managing automated systems rather than manual labor.

- Efficiency Gains:

- Increases productivity while reducing the risk of workplace injuries.

- Allows for a smaller, more skilled workforce.

- Example: Robotic palletizing systems for stacking heavy dairy product crates.

12. Compliance and Traceability

- Automation in Action:

- Automated tracking systems monitor the journey of milk from farm to factory and beyond.

- Blockchain integration ensures transparency in the supply chain.

- Efficiency Gains:

- Simplifies regulatory compliance with detailed records.

- Builds consumer trust with transparent product traceability.

- Example: Barcode or QR code systems for tracing milk batches in real time.

13. Consistency and Scalability

- Automation in Action:

- Uniform processing parameters ensure consistent product quality.

- Scalability options allow for increasing production without compromising efficiency.

- Efficiency Gains:

- Maintains product integrity across high-volume production.

- Reduces variability caused by manual processes.

- Example: Automated batching systems for consistent yogurt formulations.

Conclusion

Automation is transforming dairy processing plants by enhancing efficiency, ensuring product quality, and optimizing resource use. From precision processing and real-time monitoring to sustainable waste management, automation enables plants to meet growing consumer demand while staying competitive in a fast-evolving industry. Investments in automated technologies not only improve operational efficiency but also pave the way for innovation and scalability.

Hashtags

#DigitalTransformation #SmartFarming #FoodTech #DairyProduction #EfficientProcessing #SustainableFood #IndustryInnovations #SmartFactory #DairyMachinery #TechAdvancements #FoodSafety #DairySupplyChain #AutomationRevolution #EfficientOperations #SustainableSolutions #IndustryInsights #SmartSensors #DairyQualityControl #TechIntegration #FoodIndustryUpdates