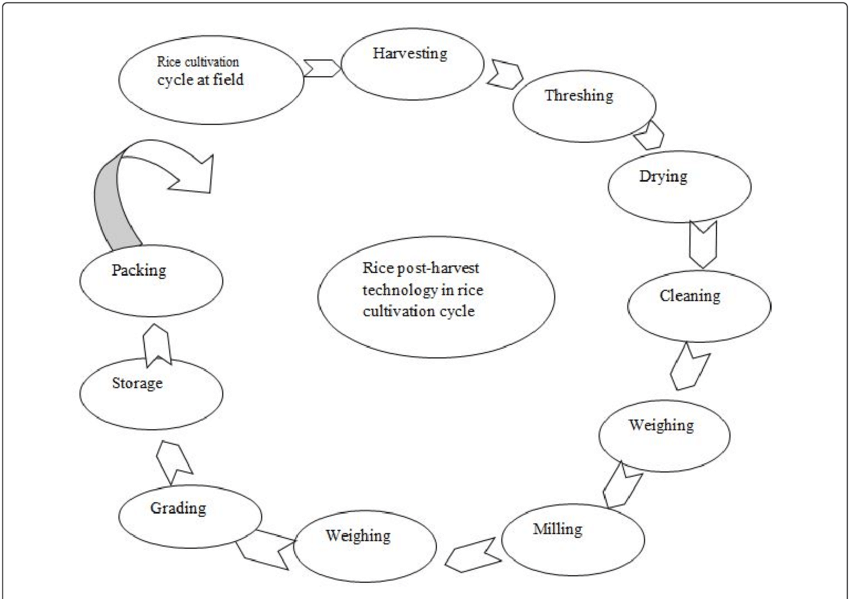

Post-harvest processes for rice are crucial for maintaining grain quality, reducing losses, and ensuring the rice reaches consumers in a usable form. These processes can be broadly categorized into the following stages:

1. Harvesting

- Timing: Harvesting is done when rice grains have reached full maturity (20-25% moisture content).

- Methods:

- Manual: Using sickles or knives.

- Mechanical: Using combine harvesters that simultaneously cut, thresh, and clean the grain.

2. Threshing

- Purpose: Separates the grains from the straw.

- Methods:

- Manual beating or trampling.

- Mechanical threshers for efficiency and reduced losses.

3. Cleaning

- Purpose: Removes impurities such as straw, stones, and dust from the threshed grain.

- Methods:

- Manual winnowing.

- Mechanical cleaning using sieves, blowers, or aspiration systems.

4. Drying

- Purpose: Reduces grain moisture content to safe storage levels (12-14%) to prevent spoilage.

- Methods:

- Traditional: Sun drying on mats or concrete floors.

- Mechanical: Using flatbed or batch dryers for uniform drying.

5. Storage

- Purpose: Protects the grain from pests, moisture, and temperature fluctuations.

- Methods:

- Use of airtight containers, silos, or bags with moisture-proof liners.

- Application of pest control measures like fumigation.

6. Milling

Milling transforms paddy into edible rice by removing the husk and bran layers. Key steps include:

- Dehusking/Hulling:

- Removes the husk to produce brown rice.

- Uses rubber roll hullers or traditional wooden hullers.

- Polishing/Whitening:

- Removes the bran layer to produce white rice.

- Performed using abrasive or friction-based machines.

- Grading:

- Sorts rice by size, shape, and quality using mechanical or optical sorters.

7. Parboiling (Optional)

- Purpose: Improves nutritional value, reduces breakage during milling, and enhances shelf life.

- Process:

- Soaking: Paddy is soaked in water.

- Steaming: Steamed to gelatinize the starch.

- Drying: Dried before milling.

8. Packaging

- Purpose: Protects rice during transportation and storage.

- Materials: Jute bags, polypropylene bags, or vacuum-sealed packaging for retail markets.

9. Quality Control

- Purpose: Ensures rice meets consumer and regulatory standards.

- Tests:

- Grain size and shape analysis.

- Moisture content measurement.

- Checking for broken grains, impurities, and uniformity.

10. Distribution

- Rice is transported to local or global markets via trucks, ships, or trains.

- Proper handling during transit ensures minimal damage to grains.

Modern Innovations

- Use of automation and AI-powered sorting for precision grading and impurity removal.

- Adoption of smart storage solutions, such as sensors for real-time monitoring of grain conditions.

- Integrated post-harvest management systems for efficiency and traceability.

Efficient post-harvest processing minimizes losses, improves grain quality, and ensures better returns for farmers and stakeholders in the rice value chain.