Innovations in water efficiency are significantly improving sustainability in beverage production, addressing the industry’s high water usage and environmental footprint. These innovations span technologies, processes, and practices to reduce water consumption, reuse water, and optimize resource management. Here are the key advancements:

1. Water Recycling and Reuse

- Technologies:

- Membrane Filtration: Advanced systems like ultrafiltration and reverse osmosis (RO) purify wastewater for reuse in non-contact applications, such as equipment cleaning or cooling.

- Electrocoagulation: Removes impurities from wastewater, making it safe for reuse.

- Examples:

- Breweries and soft drink manufacturers are reusing water from processes like bottle rinsing or pasteurization after treatment.

2. Closed-Loop Water Systems

- Technologies:

- Systems recirculate water within the production facility, minimizing fresh water intake.

- Used in processes like cooling, cleaning, and heating.

- Benefits:

- Reduces wastewater discharge.

- Cuts overall water consumption by recycling within operations.

3. Dry Cleaning Technologies

- Technologies:

- Air Rinsing: Replace water rinsing with compressed air for cleaning bottles and cans.

- Dry Lubrication: Eliminates the need for water in conveyor lubrication, commonly used in bottling lines.

- Impact:

- Reduces water usage in cleaning processes by significant margins.

4. Advanced Monitoring and IoT

- Technologies:

- Smart Sensors: Monitor water usage in real time to identify leaks, inefficiencies, and areas for improvement.

- IoT Platforms: Collect and analyze water usage data across production lines to optimize consumption.

- Benefits:

- Enables precise control of water use.

- Helps in proactive maintenance to prevent wastage.

5. Process Optimization

- Technologies:

- High-Efficiency Pasteurization: Optimizing thermal processes reduces water required for heating and cooling.

- Batch Cleaning-in-Place (CIP): Reduces water and chemical use during equipment cleaning cycles.

- Examples:

- Energy recovery systems in pasteurizers that use less water for cooling.

6. Waterless or Minimal-Water Technologies

- Technologies:

- Electrolyzed Water Systems: Generate cleaning solutions using minimal water and electricity for sterilization.

- Dry Break Systems: Minimize water usage during equipment changeovers and flushing.

- Applications:

- Particularly useful in beverage filling and packaging lines.

7. Sustainable Packaging Innovations

- Technologies:

- Lightweight Packaging: Requires less water in manufacturing processes.

- Plant-based and Biodegradable Materials: Often demand lower water inputs than traditional plastics.

- Impact:

- Reduces indirect water use in packaging production.

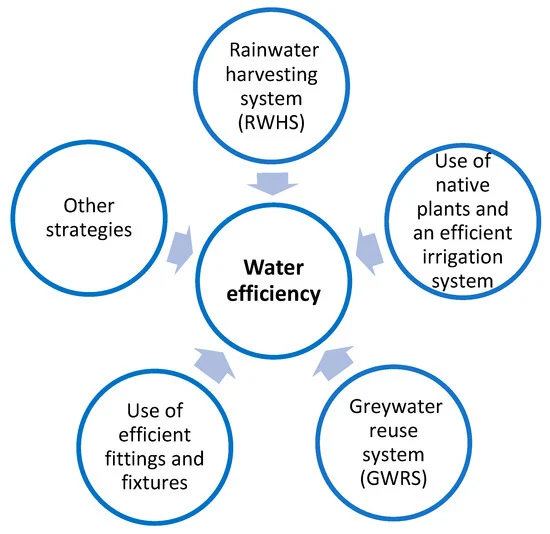

8. Rainwater Harvesting and Alternative Water Sources

- Technologies:

- On-site systems collect and treat rainwater for non-potable applications like landscaping or cooling towers.

- Examples:

- Some beverage facilities incorporate rainwater harvesting to offset their water footprint.

9. Process Integration

- Technologies:

- Cascade Systems: Reuse water sequentially in multiple processes, such as rinsing, heating, and cooling.

- Heat Exchange Systems: Utilize water from one process to preheat or cool other processes, reducing fresh water intake.

- Benefits:

- Maximizes water use efficiency across production stages.

10. Waste-to-Water Innovations

- Technologies:

- Anaerobic Digestion: Treats organic waste from beverage production to produce biogas and recover water.

- Zero-Liquid Discharge (ZLD): Advanced treatment processes recover all water from waste streams, leaving a solid residue.

- Examples:

- Breweries use spent grain digestion systems to generate clean water for reuse.

11. Renewable Energy Integration

- Technologies:

- Solar-Powered Water Heaters: Reduce water heating requirements from traditional energy sources.

- Waste Heat Recovery: Waste heat is used to preheat water, reducing energy and water demands.

- Impact:

- Enhances water efficiency by reducing the need for water-intensive energy generation processes.

12. Collaboration and Certification

- Programs:

- Beverage companies participate in global initiatives like the Alliance for Water Stewardship (AWS) to adopt sustainable water management practices.

- Obtain certifications like LEED or ISO 14001 to demonstrate a commitment to water efficiency.

- Examples:

- Companies like PepsiCo and Coca-Cola have set ambitious goals to replenish more water than they use in production.

13. Consumer Engagement

- Strategies:

- Educating consumers about water-efficient practices in beverage production.

- Promoting water-saving initiatives on product labels or marketing campaigns.

- Impact:

- Enhances brand reputation and aligns with eco-conscious consumer values.

Examples of Industry Leaders

- PepsiCo: Achieved a 25% improvement in water-use efficiency across its operations globally.

- Coca-Cola: Invested in water replenishment projects and achieved a “water-neutral” status in some regions.

- AB InBev: Introduced a global program to improve water efficiency by implementing advanced water-saving technologies.

Conclusion

Innovations in water efficiency are transforming the beverage industry by addressing the environmental and economic challenges of high water use. Through advanced technologies, sustainable practices, and a commitment to stewardship, beverage manufacturers are significantly reducing their water footprint while meeting global sustainability goals.

Hashtags

#SustainableSips #EcoConsciousDrinks #WaterWiseBeverages #GreenProduction #EfficientManufacturing #SustainableSolutions #EcoFriendlyDrinks #WaterConservingTech #SustainableBrewing #EcoEfficiency #WaterSmartProduction #SustainableBottling #EcoFriendlyPackaging #WaterSavingSolutions #SustainableBeverageIndustry #EcoInnovations #WaterConservingProduction #SustainableBeverageChoices #EcoFriendlyManufacturing #WaterWiseBrewing