The rice milling industry takes several steps to ensure the safety and quality of rice products. These measures focus on cleanliness, processing techniques, storage conditions, and adherence to food safety regulations:

1. Cleaning and Sorting

- Process: The milling process begins with thorough cleaning and sorting of the harvested rice. This removes impurities such as dirt, stones, husks, and damaged grains. Mechanical cleaners and vibrating screens are used to ensure that only high-quality rice is processed.

- Quality Assurance: By eliminating contaminants early, the industry ensures that the final product is safe for consumption and free from harmful substances.

2. Pest Control

- Process: During storage and processing, pest control measures are implemented to prevent infestation by insects like rice weevils or rodents. This is typically done through fumigation, airtight storage, and regular inspections.

- Quality Assurance: Preventing pest contamination ensures the rice maintains its quality and avoids the spread of diseases or spoilage.

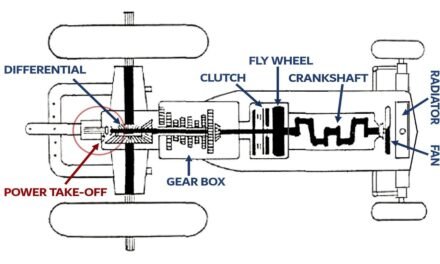

3. Use of Food-Grade Equipment

- Process: The rice milling equipment, including mills, sorters, and packaging machines, is designed to meet food safety standards. These machines are regularly cleaned and sanitized to prevent contamination between processing batches.

- Quality Assurance: Ensuring that equipment meets food-grade standards helps maintain the cleanliness and hygiene of the rice throughout the milling process.

4. Hygienic Milling Environment

- Process: Rice mills maintain a clean and controlled environment, with regular cleaning schedules for all facilities. This includes sanitizing surfaces, air filtration systems, and minimizing the exposure of rice to contaminants.

- Quality Assurance: A hygienic environment helps prevent microbial contamination, ensuring the rice remains safe for consumption.

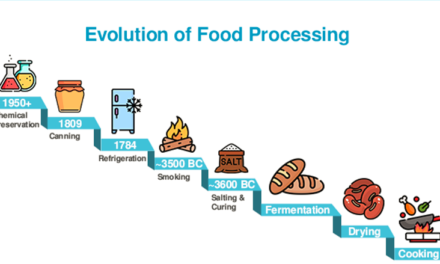

5. Adherence to Food Safety Standards

- Process: The rice milling industry complies with local and international food safety regulations, such as HACCP (Hazard Analysis and Critical Control Points) and GMP (Good Manufacturing Practices). These systems involve monitoring and controlling critical stages of production to minimize risks.

- Quality Assurance: Compliance with these standards ensures that the rice meets safety requirements and prevents potential health hazards during production.

6. Enrichment and Fortification

- Process: To improve the nutritional quality of rice, especially white rice, milling companies may fortify rice with essential vitamins and minerals like iron, folic acid, and B vitamins. This is done by food safety and regulatory standards.

- Quality Assurance: Fortification ensures that consumers receive rice with adequate nutritional value, contributing to public health and safety.

7. Quality Control Testing

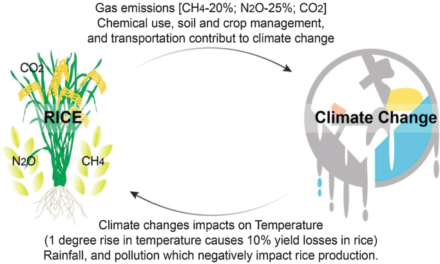

- Process: Before rice products are shipped out, quality control testing is conducted to check for moisture content, broken grains, and the presence of foreign materials. Additionally, chemical and microbiological testing may be performed to check for pesticide residues, mycotoxins, or harmful pathogens.

- Quality Assurance: Testing helps ensure that rice products are free from contaminants and meet regulatory standards for safety and quality.

8. Packaging and Storage

- Process: Rice is packaged in clean, food-safe materials to protect it from contamination during transport and storage. Packaging also provides protection against moisture and pests, which could affect the quality of the rice.

- Quality Assurance: Proper packaging and storage help preserve the quality of rice and extend its shelf life while ensuring that it remains safe for consumption.

9. Traceability and Transparency

- Process: Modern rice mills often implement traceability systems to track rice from the farm to the consumer. This system ensures that rice can be traced back to its origin in case of any quality issues or food safety concerns.

- Quality Assurance: Traceability enhances transparency and accountability, enabling quick responses to potential issues with specific batches of rice.

10. Regular Audits and Inspections

- Process: Rice mills undergo regular audits and inspections by food safety authorities or third-party certification bodies to ensure compliance with food safety standards and quality protocols.

- Quality Assurance: Audits help identify potential risks in the production process and ensure that corrective actions are taken to maintain product safety and quality.

The rice milling industry ensures the safety and quality of rice products through rigorous cleaning, pest control, hygienic practices, food safety compliance, and regular quality control checks. These measures help produce rice that is both safe and of high quality for consumers.